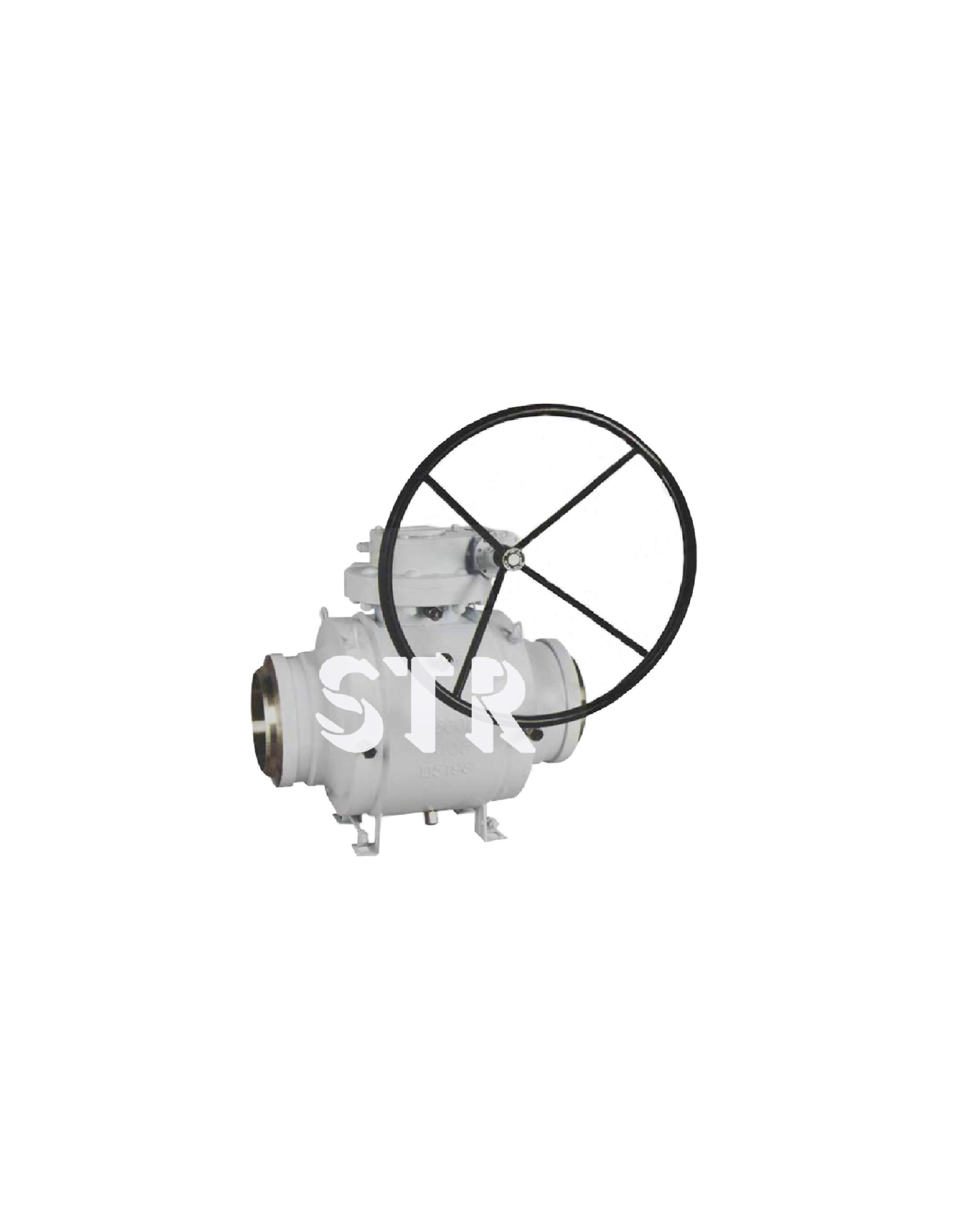

FULLY WELDED BALL VALVE

FULLY WELDED BALL VALVE

DESCRIPTION AND FEATURES

This is welded by forged steel. The forging materials are subjected to ultrasonic examination according to ASME nondestructive flaw detection requirements. The welding slope on the connection face is subjected to liquid penetration examination. The stem, fixed shaft, ball, seat and seat ring are subjected to chemical nickel plating according to ASTM B733 and B656. In addition, various corrosion resistance materials are available for users to select.According to customer requirements, the valve materials can be selected according to NACE MR 0175/ISO 15156 or NACE MR 0103, and strict quality control and quality inspection should be carried out during the manufacturing so as to fully meet the requirements in the standards and meet the service conditions in sulfurization environment.

Standard, construction and application

Design and Manufacture: API 6D, ASME B16.34, EN12516, DIN3357-1

Face to face(end to end): ANSI B16.10,API 6D

Fire-safe: API 607,API 6FA

Butt welded end: ANSI B16.25

Test and inspection: API 98,API6D

Material: Carbon Steel & Stainless Steel

Optional Locking Device or Stem Extension

Ends Connections: W.ExW.E, W.ExFLG

Optional Direct Mounting to ISO 5211

Full Port or Regular Bore

Double Block and Bleed

NACE MR-01-75

Normal Size Range: 2"-24" DN15 to DN600

Normal Pressure Rating: ANSI #150 to 900, PN10 Thru PN150